|

VISUAL AND MECHANICAL TEST |

|||||||

| Typically, solder connectors must be free of imperfections. In the case of transmission of forces using connectors arc welding processes by melting and forging with ceramic ferrule or shielding gas , welds and breaks should be examined for the presence of pores , lack of fusion , cracks, blowholes and inclusions. |

|||||||

|

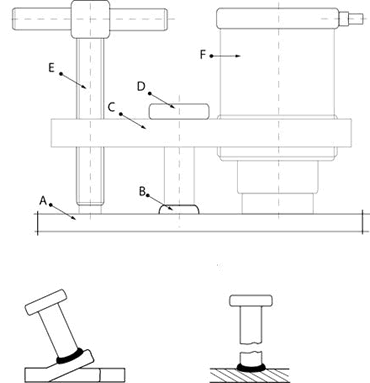

Example of connectors tensile testing A - Workpiece B - Welding C - Bridge D- connector E - level adjustment screw F - Hydraulic cylinder |

||||||

|

|||||||

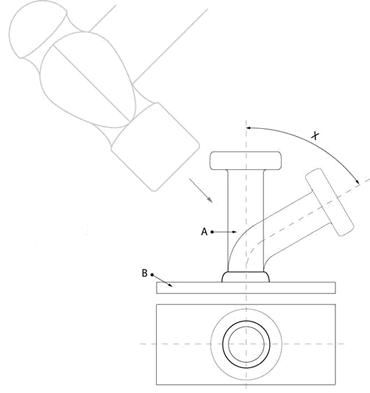

FIGURE OF BENDING : A connector Workpiece B X 60 ° |

|||||||

| - Tensile Test. Used for connector welding processes by melting arc and forging with ceramic ferrule or shielding gas. Using an appropriate traction device the connectors welded undergo axial tension until fracture. If the base metal is broken or the connector on the outside of the weld after is deformated, the weld is considered satisfactory . If full quality is required according to EN 729-2, it is not permitted any breakage in the welding zone. If standard quality is required according to EN 729-3, with respect to the welding connector arc process by melting and forging with ceramic ferrule or shielding gas, fractures located in the welding area are only allowed if it reaches the nominal resistance in tension of the material of the connector. The imperfections on the surfaces of breakage must agree with the limit specified in the general section of examinations and tests . - Macrographic review . Required for welding processes connector arc by melting and forging with ceramic ferrule or shielding gas. In the case of force transmission and full quality requirements according to EN 729-2, imperfections should not exceed the limits given. The microcracks can not be taken into consideration. - Radiographic Examination. Only required for connectors by arc welding, melting and forging with ceramic ferrule protective gas with a diameter d> 13 mm, used for the transmission of forces and in which no tensile tests are performed. To perform the test, the connectors should be cut just below the collar. When radiographic examination is required in accordance with EN 1435 it must be done with the class B technique . Imperfections should not exceed the limit specified in paragraph of generalities, of examinations and tests. |

|||||||

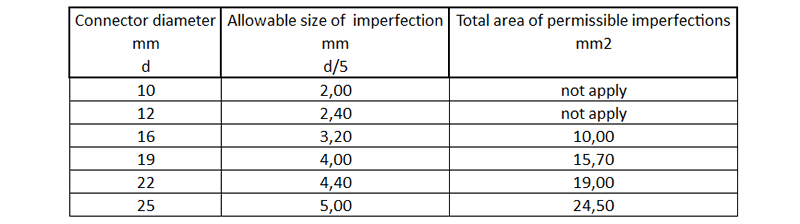

| Relations table 1.13 (*) - Relations between connector diameter, allowable size of imperfections and the total area of permissible imperfections mm^2. | |||||||

|

|||||||

|

|||||||